A Very CoDES Winter Greeting

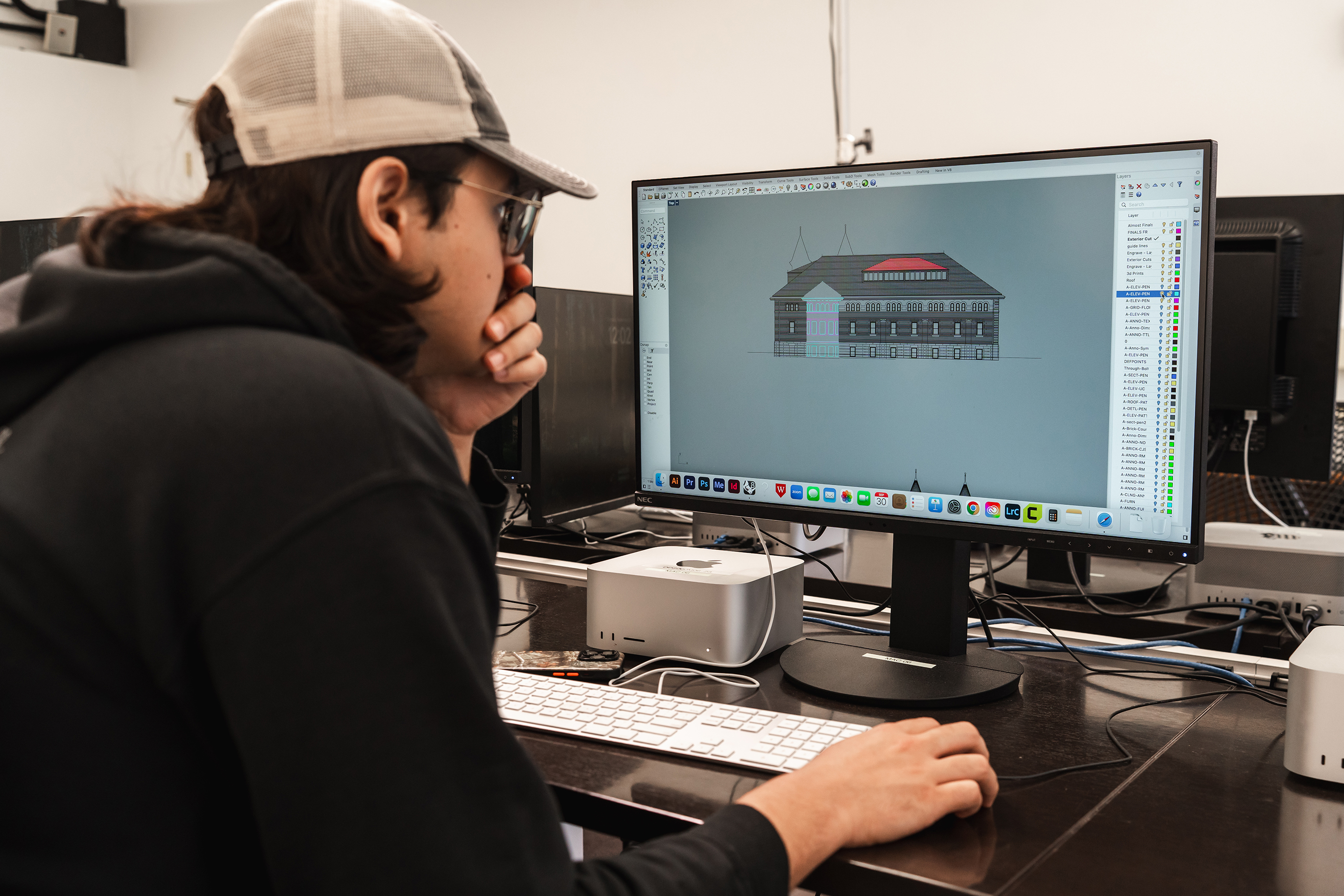

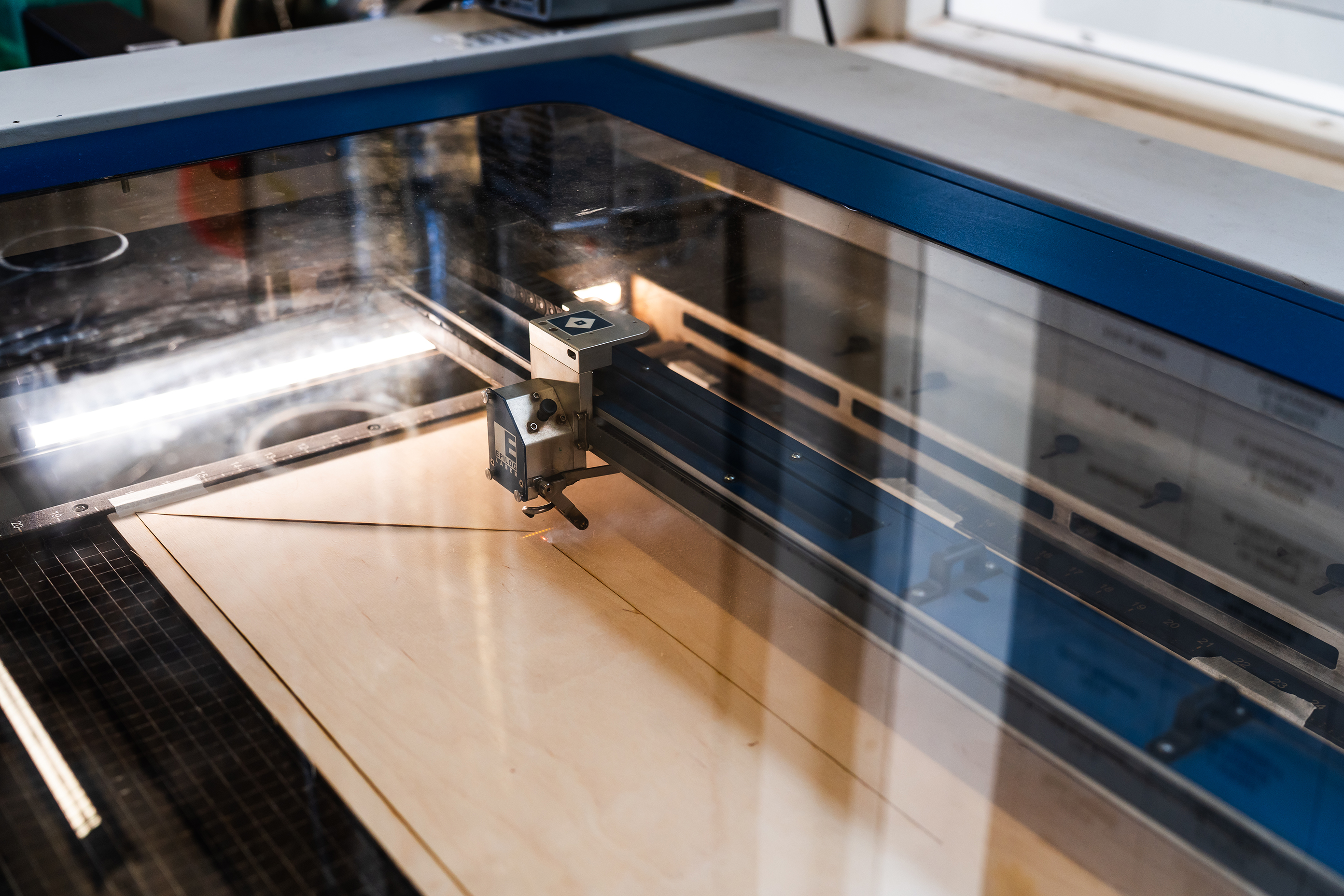

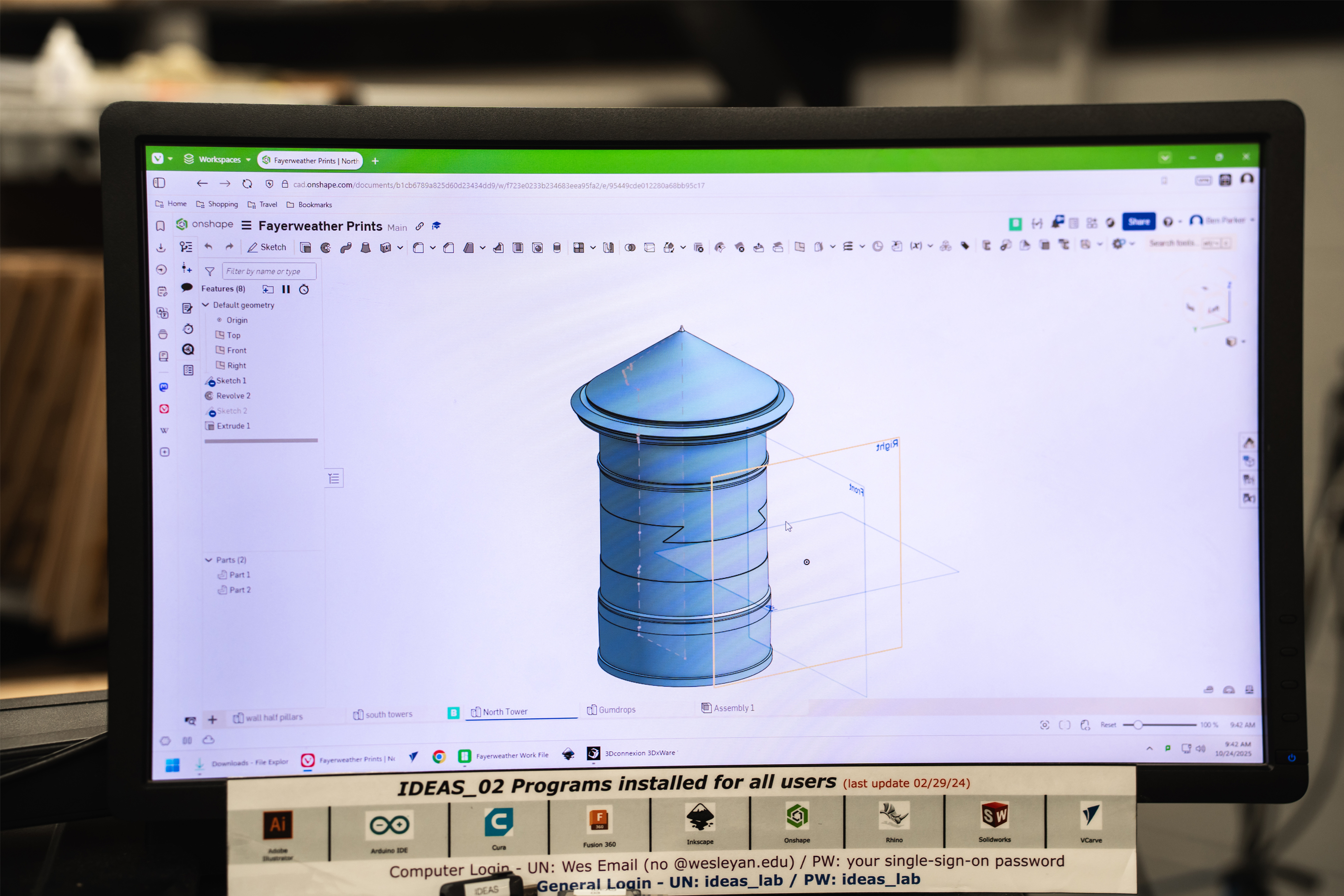

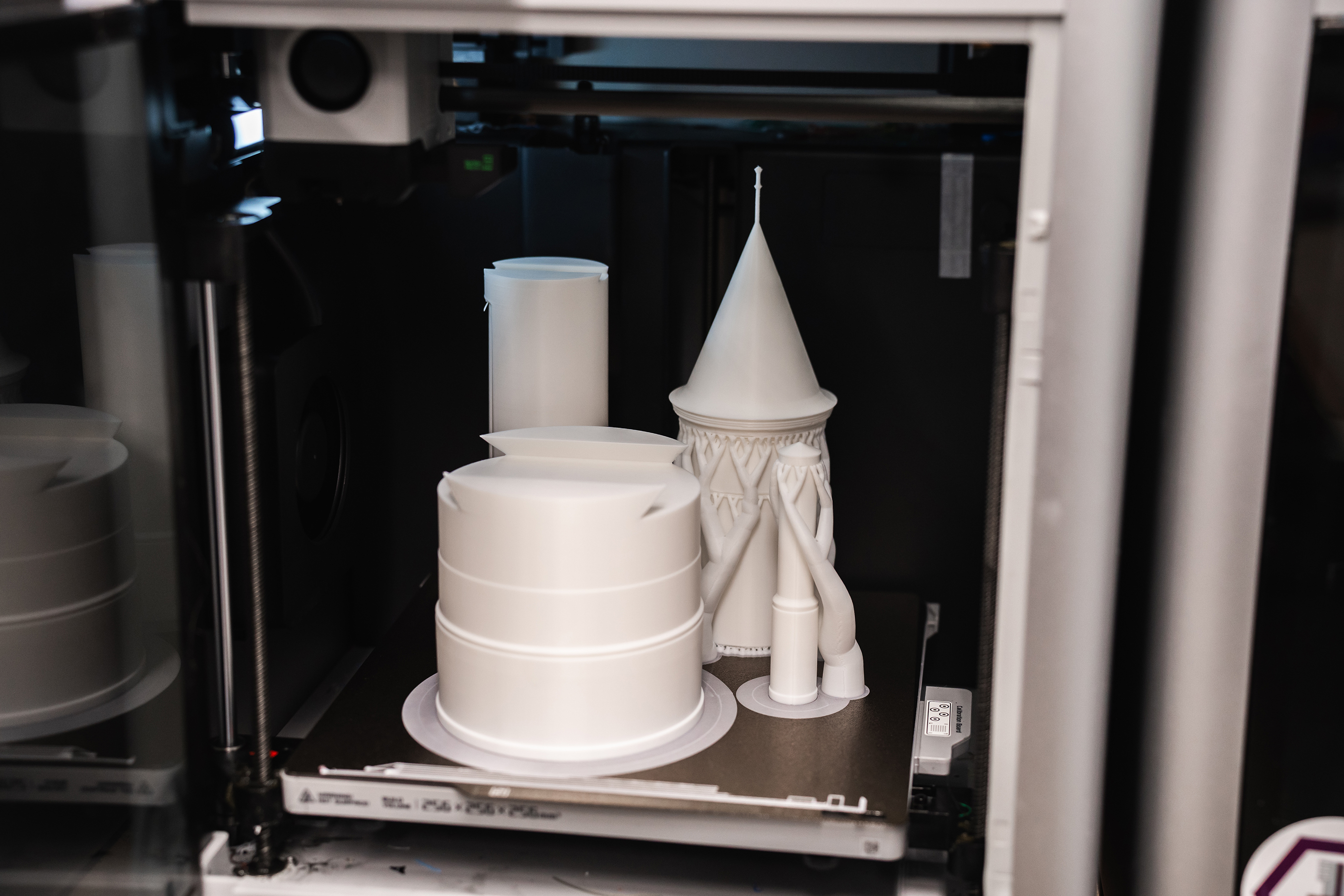

With Fall semester classes coming to a close and temperatures dipping below freezing, Wesleyan’s annual holiday greeting ushers in the end of the year with warm wishes and good cheer. This year’s greeting offered a whimsical take on iconic Fayerweather and the boundless imagination of our students. But instead of fairy godmothers, magical elves, or benevolent spirits working while the campus slept, a team of students, College of Design and Engineering Studies (CoDES) staff, and University Communications captured the magic of the season as only Wesleyan could—with some campus inspiration, CoDES ingenuity, and a ton of makerspace fun. Read on for a behind-the-scenes look at the making of the 2025 Wesleyan holiday video.

Video: Holiday greetings from Wesleyan University

Not pictured: Arielle Gold ’27, Oscar Hershkowitz ’28, Noah Lim ’27, Jacob Poore ’27, Juliette Sullivan ’27, Vin Wiemelt ’29